設計一個低溫氣體系統,Designing a Cryogenic System

CONCOA低溫系統設計用于保證需要的應用氣體的壓力和流量。液態氣罐的性能常常被人有所誤解。液態氣 罐的技術指標常常列出氣相回流在350-400cfh的范圍。然而,實際上最大可承受的沒有壓降的流速僅僅在200-250 cfh。限制因素在于氣罐的壓力常常形成環流(coil circuit)。

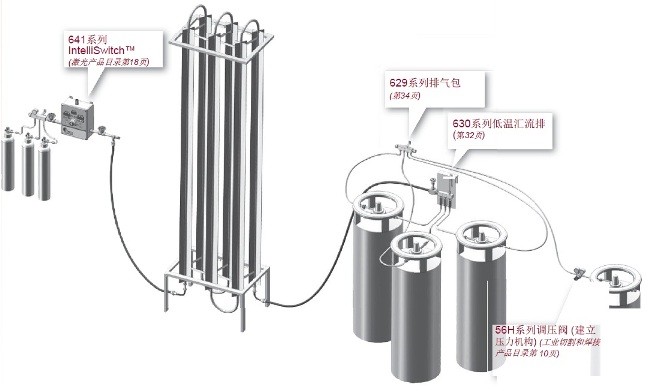

要克服這種狀況,使用者可以使用液態回流閥連接到外部蒸發器上去。在液態氣瓶壓力構成回流之前和壓力回 落之前,可以達到700-800cfh的流速幾個小時。如下圖所描述的,CONCOA將630系列低溫匯流排, 629系列排氣包 與一個以擴展液態罐性能到超過4,000cfh的輔助建立壓力回路結合到一起。

這個可以這樣達成:使用從一個附加氣 瓶調節氣相,將連接到630系列匯流排的供氣罐的液體壓出。

無論從低溫匯流排壓出的液體量多少,蒸發器選型都 必須是1.5倍于希望的流量大小。環境溫度對蒸發器的性能至關重要,因此蒸發器的安裝位置與布置都必須有所考慮。設計的系統在同CONCOA的IntelliSwitch系列全自動電子切換系統一起工作時,可以連續操作。

其關鍵之處在于讓CONCOA的低溫系統輸出。

美國CONCOA公司低溫氣體系統

CONCOA cryogenic systems are designed to maintain the pressure and flow of demanding applications. Liquid can performance is often misunderstood. The liquid can specificationstypically list gas phase withdrawal in the range of 350-400 cfh. However, in practice themaximum sustainable flow rate without pressure drop is only 200-250 cfh. The limiting factoris often the can’s pressure building coil circuit.

To overcome this condition the user may use the liquid withdrawal valve connected to an external vaporizer. Flow rates of 700-800 cfh are achievable for a couple of hours beforethe liquid cylinder’s pressure building circuit is saturated and pressure falls. As illustrated below CONCOA has packaged the 630 series cryogenic manifold, 629 series vent kit and an auxiliary pressure building circuit to extend liquid cans performance to over 4,000 cfh. This is achievable by using the regulated gas phase from an additional cylinder to push liquid out of each supply can connected to the 630 manifold. Regardless of the volume of liquid pushed out of the cryogenic, manifold the vaporizer must be sized 1.5 times the desired flow capacity. Ambient temperature is vital to the vaporizer’s performance so location and geography must be considered.

A continuous operation is achievable when coupled with CONCOA’s IntelliSwitch series automatic switchovers. The bottom line is CONCOA cryogenic systems deliver the results.